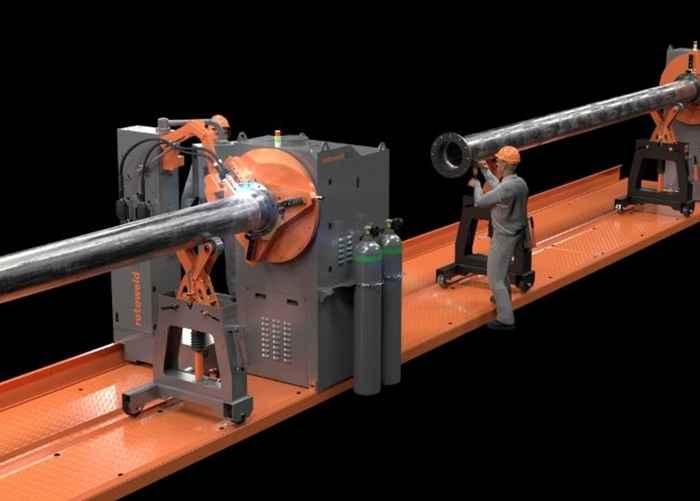

Welding Automation – Solution for Pipe Fabrication

At Fenatek, we bring you cutting-edge welding automation solutions designed to transform your fabrication processes. With the Rotoweld 3.0, you gain access to the most advanced automated welding technology available, enabling unmatched productivity, precision, and efficiency for your workshop.

Applications of the Rotoweld 3.0 in Welding Automation

The Rotoweld 3.0 is designed to address a wide range of industrial welding applications, making it the ideal choice for:

- Pipe Fabrication: Streamlines the welding of pipes for oil, gas, and petrochemical industries.

- Pressure Vessels: Ensures precision and consistency in manufacturing boilers, tanks, and other pressure-holding components.

- Shipbuilding: Automates critical welding tasks in constructing ships and marine vessels, improving efficiency and reducing labor dependency.

- Structural Welding: Enhances the fabrication of steel structures used in construction and heavy industries.

- Energy Sector: Facilitates high-quality welding for pipelines, wind turbines, and energy-related projects.

Why Choose the Rotoweld 3.0 for Welding Automation?

- Unrivaled Productivity

- Achieve industry-leading productivity with an average of 300 dia inches per day.

- Seamlessly handle pipe diameters from 3 inches to 42 inches.

- Robust pipe stands with a capacity of up to 10,000 lbs.

- Revolutionary PerfectPass-iQ™ Technology

- Real-time automatic adjustments ensure consistent weld quality.

- Simplified operations allow ASME Section 9 welds at the press of a button.

- Optimized arc-on time delivers a 400% productivity boost for your shop.

- Faster Welding with Precision

- Root-pass, fill-pass, and cap are completed in record time, adapting to various joint preparation conditions.

- Welding times:

- Standard wall pipes: 1 minute per dia inch.

- Heavy wall pipes: 1.5 minutes per dia inch.

Image Gallery

1

Exceptional ProductivityWith an average of 300 dia inches per day and rapid welding speeds (1 min/dia inch for standard pipes), the Rotoweld 3.0 maximizes throughput and minimizes downtime in your fabrication shop.

2

PerfectPass-iQ™ TechnologyThis advanced system automatically adjusts welding parameters in real time, adapting to variations in pipe fit-up and preparation. The result is consistently high-quality welds with minimal operator intervention.

3

Prodatalog™ Monitoring SystemThe Rotoweld 3.0 includes a sophisticated web-based tracking tool that monitors, logs, and reports welding performance, ensuring quality control and efficient process management

4

Customizable ConfigurationsAvailable in single, twin-bay, or heavy-duty models, the system caters to your specific production requirements. Optional integrated fume extractors enhance workplace safety and cleanliness.

5

Operator-Centric DesignFeatures like UV protection, ergonomic positioning, and a camera-based control system ensure safer working conditions, reduced fatigue, and increased operator productivity.

6

Versatile Welding ProcessesCompatible with GMAW, SAW, and FCAW/MCAW, the Rotoweld 3.0 accommodates diverse welding needs, making it a versatile addition to any fabrication environment.

Welding Automation