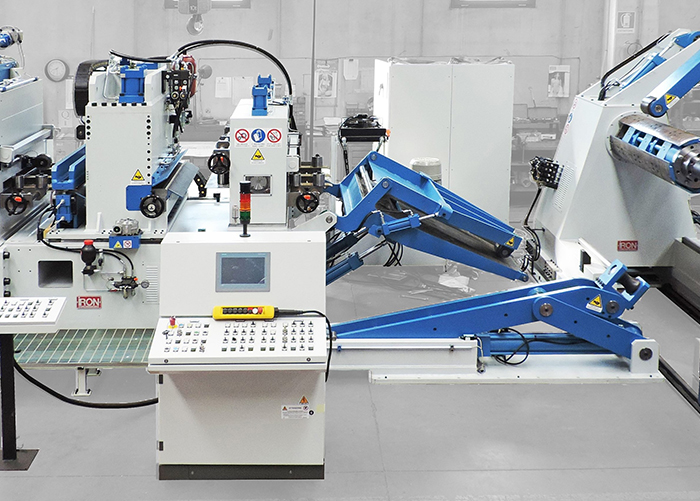

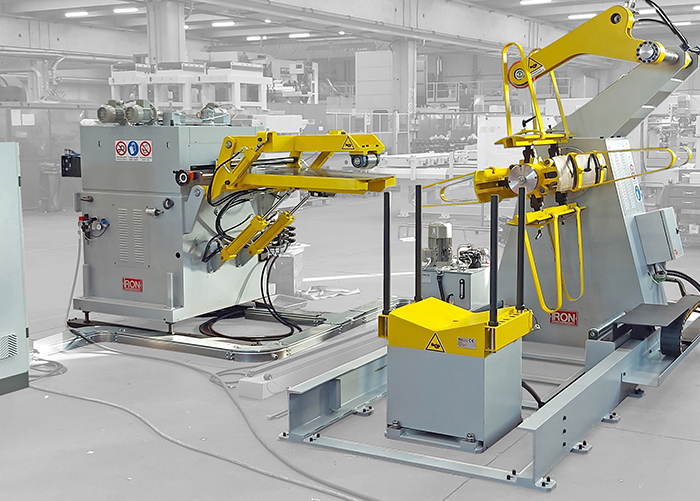

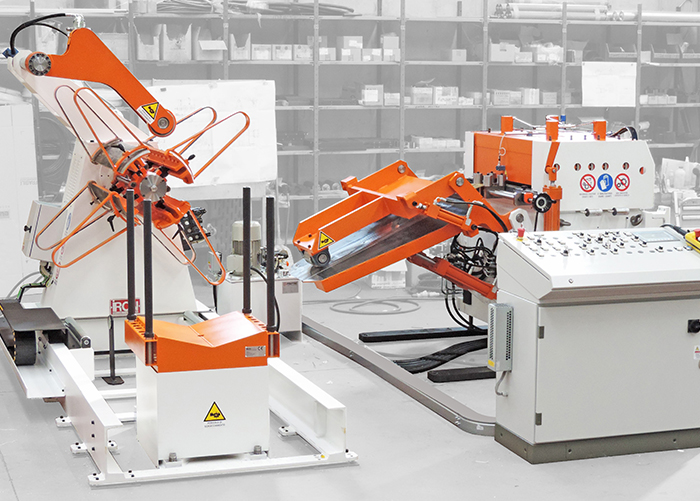

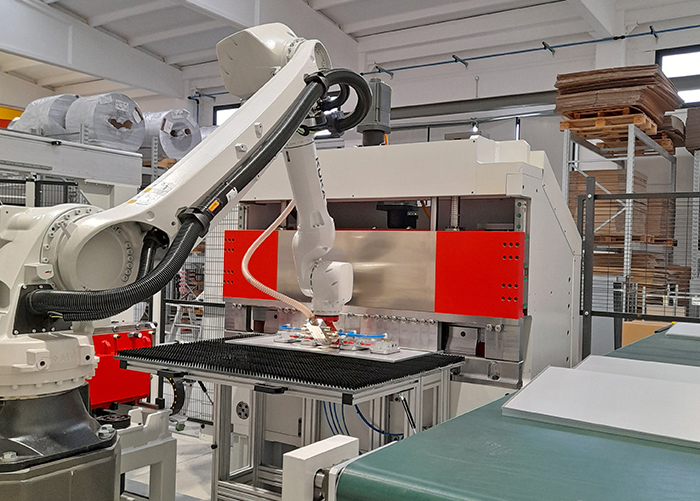

Sheet Metal Processing Lines

Fenatek proudly partners with IRON, the global leader in large-scale, customized sheet metal processing solutions. Known for their innovation and excellence, IRON also holds the top spot in Europe for producing advanced coil handling systems for blanking line feeding and press brake systems, including the largest and most complex designs.

Why Sheet Metal Processing Lines?

IRON’s reputation for delivering state-of-the-art belt feed lines and coil handling systems has cemented its place in the international market. These innovations are particularly valued in the automotive industry, where automation and precision are paramount. With over five decades of experience, IRON continues to lead the way by integrating cutting-edge technology into every solution, ensuring reliability and efficiency for clients worldwide.

What is Sheet Metal Processing?

Sheet metal processing encompasses a variety of mechanical operations applied to metal sheets, tailored to meet the diverse needs of manufacturing industries. The methods employed depend on the final product requirements, making these machines essential for producing high-quality outputs across multiple sectors.

Why Invest in a Sheet Metal Processing Line?

Sheet metal processing machines streamline complex operations like:

- Cutting

- Stamping

- Bending

- Perforating

- Ironing

- Spinning

- Roll forming

Our sheet metal processing lines include a wide range of specialized equipment to meet diverse industrial needs:

- Coil Handling: Self-centering motorized and braking unwinders for efficient material handling.

- Slitting: Longitudinal cutting lines for precision processing.

- Cut to Length: Advanced blanking and cutting lines tailored for optimal performance.

- Punch Press & Bender: State-of-the-art punching and paneling systems for intricate designs.

- Temnos: Innovative coil laser cutting solutions for high-precision tasks.

- Customized Lines: Tailor-made projects designed to meet unique client requirements.

Applications

- Automobile and truck body production

- Aircraft fuselages and wings

- Medical equipment

- Architectural structures

- Commercial kitchen tools

- Control panels for industrial systems

Innovation and Quality

Since its establishment in 1969, IRON has continually raised the bar in the sheet metal processing industry. With the introduction of IRON QUALITY in 1999, the company implemented a robust quality management system, guaranteeing superior reliability and performance. This commitment to excellence is reflected in its groundbreaking advancements, such as the adoption of pneumatic and hydraulic feeders, which marked significant milestones in automation technology.

For inquiries about our range of Fastener Insertion Machines, contact us today at sales@fenatek.com. Let our experts assist you in finding the perfect solution for your business needs!

Image Gallery