Pipe Beveling Machine

Pipe beveling machines are essential for industries that demand precision, efficiency, and versatility in cutting and beveling pipes. Designed for optimal performance, these machines simplify weld preparation and ensure consistent results, even in challenging environments. Whether for small-scale projects or large industrial applications, pipe beveling machines enhance productivity while reducing operational costs.

Engineered to meet the highest standards of durability and precision, pipe beveling machines are a cornerstone for industries that require seamless operations and minimal downtime. Their innovative designs ensure reliability and ease of use, making them indispensable tools for professionals who prioritize accuracy and efficiency in every project.

Applications

Pipe beveling machines are widely used in industries such as:

- Oil and Gas: For precise weld preparation in pipelines.

- Construction: Ensuring accurate cuts and bevels in structural pipework.

- Shipbuilding: Facilitating pipe fabrication for marine applications.

- Power Plants: Streamlining maintenance and installation of piping systems.

- Manufacturing: Providing efficient cutting and beveling for production lines.

Advantages of Using Pipe Beveling Machines

- Save time and reduce manual effort in weld preparation.

- Achieve high precision and clean cuts for improved welding quality.

- Adapt to varying pipe sizes and materials with adjustable settings.

- Minimize operator fatigue with ergonomic and user-friendly designs.

Solutions we provide

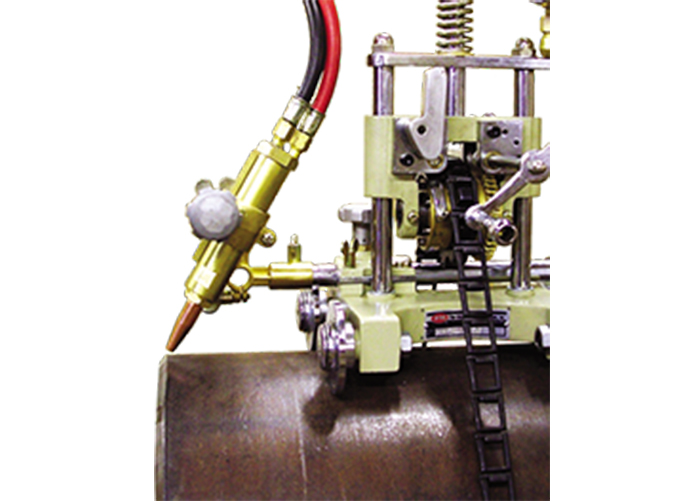

"Saddle-Type" Beveling Machine

Standard "Saddle-Type" Beveling

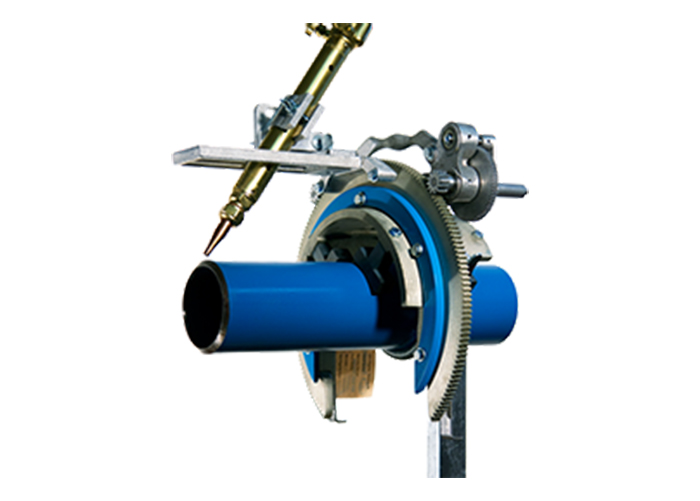

Band-Type Beveling Machine

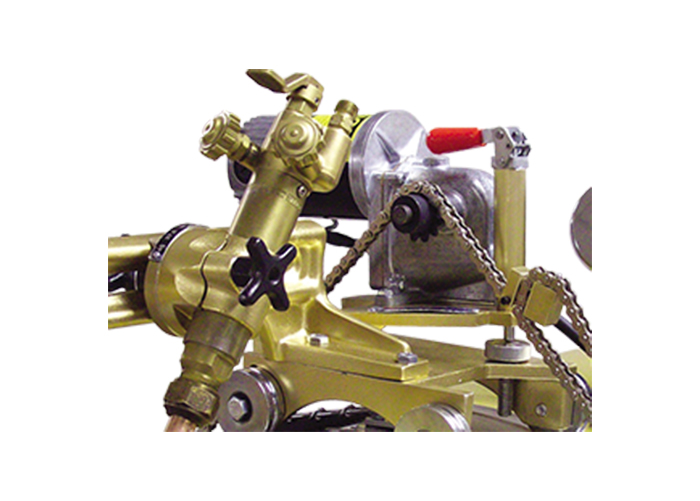

4 Wheel Heavy Duty Motorized Beveling