Magnets for Positioning and Holding

Magnetic positioning and holding solutions are revolutionizing industries by providing efficient, reliable, and precise tools for aligning and securing materials in various applications. These tools leverage the power of magnetism to streamline processes in metal construction, switch cabinet assembly, sawing, deburring, and beyond. At Fenatek, we pride ourselves on offering world-class magnetic tools and solutions sourced from industry leaders like Strong Hand Tools. Our range of magnets for positioning and holding ensures enhanced productivity, precision, and safety for our clients.

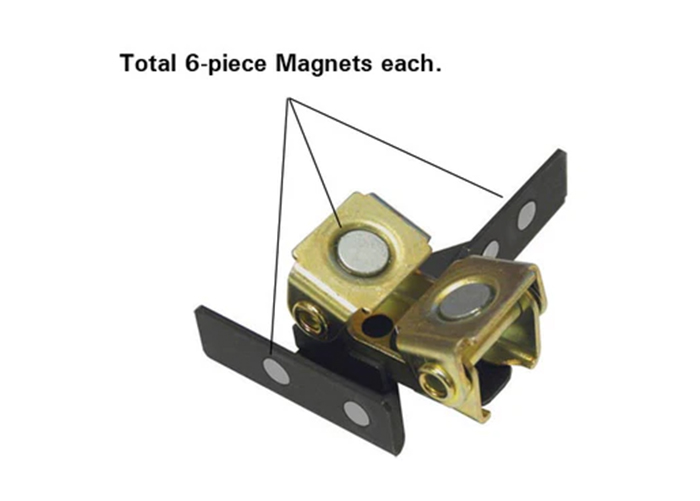

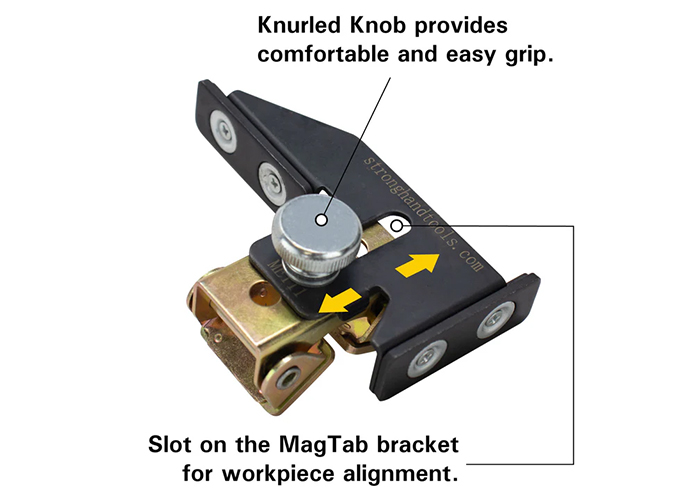

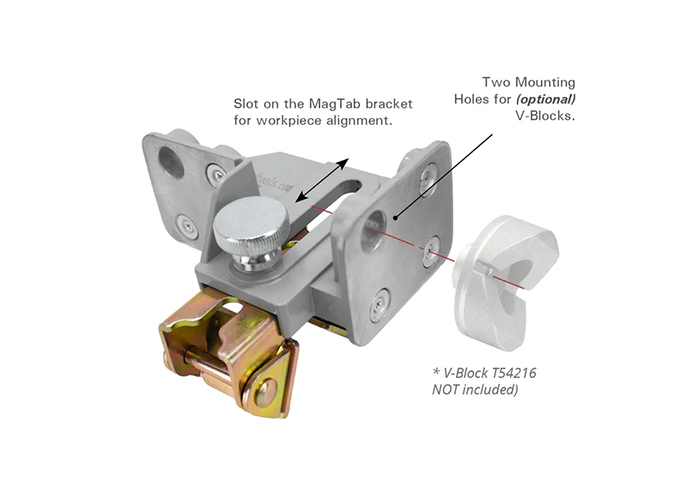

Magnetic positioning is the process of using the unique magnetic fingerprint of materials to map, align, and secure components during assembly or fabrication. Our products provide unmatched efficiency and flexibility, whether for lifting thin sheet metals, aligning tabs, or holding irregularly shaped materials in place. From heavy-duty lifting magnets capable of handling loads up to 490 kg to lightweight solutions designed for tack welding and sub-assembly work, Fenatek offers a versatile lineup to meet the diverse needs of professionals across industries.

Applications

Our magnets for positioning and holding are ideal for:

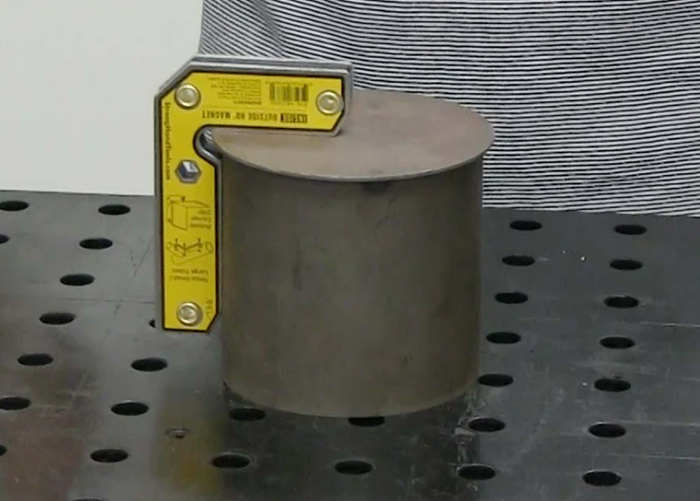

- Metal Fabrication: Align and hold steel plates, pipes, and irregular shapes with ease.

- Welding: Tack weld materials securely while keeping inside areas accessible.

- Load Handling: Lift thin and heavy sheet metals with confidence using our TML magnets.

- Assembly Work: Build and position lightweight structures with precision using MagTabs and V-Pads.

- Construction: Secure materials during sawing, deburring, or switch cabinet installations.

- Field Applications: Portable and durable solutions for on-site fabrication and repair.

Why Choose Fenatek?

- Premium Products: Our partnership with Strong Hand Tools ensures the highest quality and performance in every product.

- Customized Solutions: Whether you need magnets for lifting, holding, or positioning, we provide tailored solutions to meet your unique requirements.

- Expert Support: Our experienced team is ready to assist you in selecting the right tools and ensuring seamless integration into your workflows.

- Lifetime Free Service: As part of our commitment to customer satisfaction, Fenatek offers lifetime free service for all products, ensuring long-term value and peace of mind.

Solutions we provide