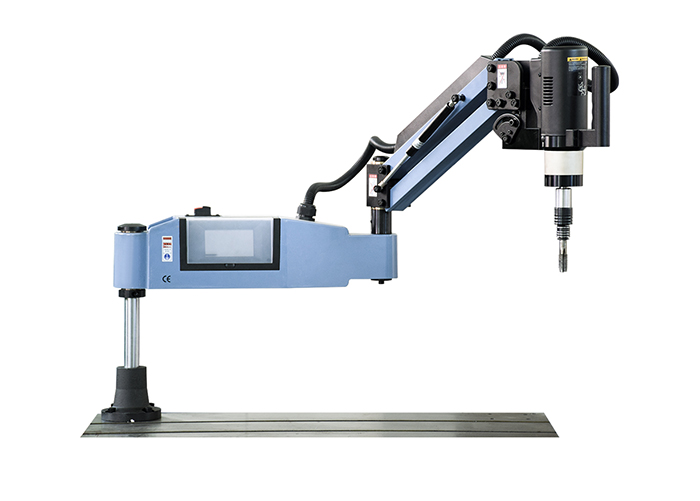

Electric Tapping Machine

Electric tapping machines represent the future of industrial threading, offering a significant leap in both speed and accuracy compared to traditional manual methods. With their ability to handle a wide range of materials and sizes, they are ideal for companies looking to optimize their manufacturing processes. Whether you’re dealing with high-volume production or precise custom jobs, these machines are engineered to deliver consistent results, minimize errors, and reduce labor costs. By integrating advanced technology, electric tapping machines enhance overall productivity while ensuring a higher standard of precision for every operation

Key Features

- Versatility: Perfect for threading metals like steel, aluminum, and alloys.

- Efficiency: Servo motor-driven designs for smooth and consistent performance.

- Precision: Automatic oil sprayers ensure a seamless tapping process.

- Flexibility: 360° adjustable arms accommodate threading in tight or challenging spaces.

- Durability: Engineered with robust materials for long-lasting use across heavy-duty applications.

Applications

Electric tapping machines are indispensable in industries that demand high accuracy and productivity:

- Automotive: Engine components, chassis parts, and structural frames.

- Aerospace: Precision threading for lightweight and durable materials.

- General Manufacturing: Ideal for creating threaded components in machinery and tools.

Why Choose Us?

We provide top-quality electric tapping machines designed to enhance productivity while maintaining strict standards of precision and reliability. Our commitment to innovation ensures that our machines exceed expectations across industries. For more information, contact us at sales@fenatek.com.

Image Gallery