Electric Cutters

Fenatek brings cutting-edge electric cutters designed to revolutionize the plastic tube cutting process. From extrusion lines to coiled reels, our advanced cutting systems deliver unmatched speed, precision, and efficiency. Engineered to meet the demands of diverse industries, including automotive, biomedical, renewable energy, and assembly lines, our solutions redefine productivity and quality.

Applications of Electric Cutters

Our electric cutters cater to a wide range of applications, making them ideal for:

- Extrusion Line Cutting: Seamlessly cut plastic tubes directly from extrusion, reducing labor and processing time while ensuring clean, precise cuts.

- Reel-to-Tube Cutting: Cut coiled tubes with precision, eliminating waste and enhancing operational efficiency.

- Custom Tape Cutting: Ideal for cohesive and adhesive tapes, delivering consistent results for packaging, assembly, and industrial needs.

- Semi-Automatic Cutting: Suitable for variable tube diameters, ensuring flexibility in production lines.

- High Cutting Precision: All products deliver exceptional cutting accuracy, ensuring consistent results across various applications and materials.

- Customizable and Versatile: Adaptable to different tube diameters, lengths, and material types, with options for additional accessories like cutting bushes and uncoilers.

- User-Friendly Design: Simplified operation with intuitive controls, quick format changes, and programmable settings for efficient workflows.

- Industry 4.0 Ready: Advanced automation features with compatibility for programmable systems, USB memory storage, and seamless integration into production lines.

Electric Cutters options we provide

- Fenatek’s Speedy Cut sets the standard for high-speed precision cutting. With its electronically driven motor and rotating blade, it achieves up to 65 cuts per second while maintaining a cutting accuracy of ±0.1%. Designed to integrate seamlessly with extrusion lines or reel-fed systems, Speedy Cut is Industry 4.0 ready, allowing for programmable settings and quick format changes with replaceable cutting bushes.

- The Tape Cut delivers unparalleled efficiency in cutting cohesive and adhesive tapes. Available in manual and automatic versions, it ensures precise cuts with lengths ranging from 20 to 999 mm and an accuracy of ±2 mm. This user-friendly cutter streamlines workflows with batch processing and built-in counters, making it an essential tool for industrial and packaging applications.

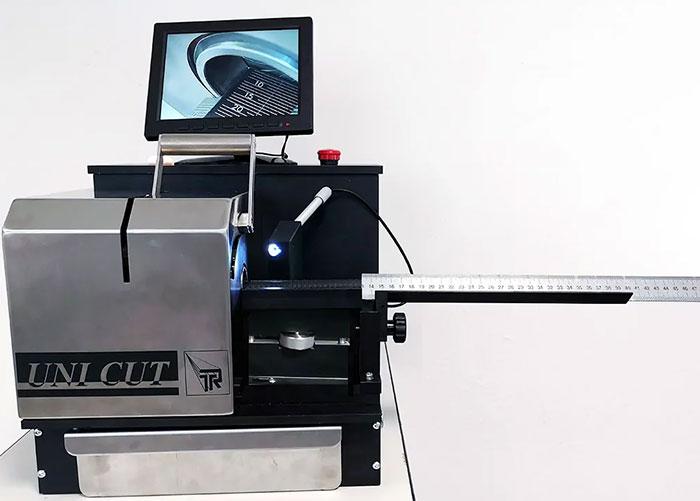

- Fenatek’s Uni Cut offers limitless cutting flexibility for various tube diameters. Available with either a dedicated cutting bushing or an innovative double Iris bushing, Uni Cut ensures high performance and precision (±0.5 mm) for tubes ranging from 2 to 25 mm. Its semi-automatic design and adaptability make it perfect for industries requiring precision cuts without length limitations.

- The Simply Cut is designed for cutting a wide range of materials, including PVC, EVA, PU, silicone, and coextruded materials. Featuring a high-speed rotating blade and three operational modes, it guarantees consistent, high-quality cuts. Optional accessories like motorized uncoilers enhance its performance, making Simply Cut a versatile and efficient solution for industrial applications.

Solutions we provide

Speedy Cut

- Pulling capacity: 1000 kg

- Battery recharging time: approx. 8 hrs.

- Pushing speed: fast 3 Km/h – slow 1,5 Km/h

- L x W x H: 960mm X 455mm X 1050mm

- Weight: 85 Kg

Tape Cut

- Pulling capacity: 1000 kg

- Battery recharging time: approx. 8 hrs.

- Pushing speed: fast 3 Km/h – slow 1,5 Km/h

- L x W x H: 960mm X 455mm X 1050mm

- Weight: 85 Kg

Uni Cut

- Pulling capacity: 2000 kg

- Pulling speed: fast 5 Km/h – slow 2,5 Km/h

- L x W x H: 1375mm X 620mm X 1000mm

- Speed control: Butterfly type

- Weight: 130 kg

Simply Cut

- OT-900L UP OT 3000 Kg

- OT-1200L UP TO 4000 Kg

- L x W x H: 1530mm X 780mm X 1040mm

- Battery recharging time: Approx. 8 hrs.

- Weight: 190 kg

Cutters

Features

1

High Cutting PrecisionAll products deliver exceptional cutting accuracy, ensuring consistent results across various applications and materials.

2

Customizable and VersatileAdaptable to different tube diameters, lengths, and material types, with options for additional accessories like cutting bushes and uncoilers.

3

User-Friendly DesignSimplified operation with intuitive controls, quick format changes, and programmable settings for efficient workflows.

4

Industry 4.0 ReadyAdvanced automation features with compatibility for programmable systems, USB memory storage, and seamless integration into production lines.

5

Enhanced Speed and Efficiency Designed to minimize processing time while maintaining high-speed cutting performance, suitable for extrusion lines and reel-based systems.

6

Durable and ReliableBuilt with high-performance motors and premium components, ensuring longevity and consistent performance in demanding industrial environments.