Laser Marking Machines

Fenatek’s range of Laser Marking Machines combines cutting-edge technology, versatility, and precision to cater to diverse industry needs. We offer three primary types of laser marking technologies: Fiber Laser Marking Machines, UV Laser Marking Machines, and CO2 Laser Marking Machines. Each is uniquely tailored to meet specific applications, ensuring high-quality performance and durability.

Fiber Laser Marking Machine

The Fiber Laser Marking Machine is engineered for efficiency and high precision. It is ideal for marking on metal materials and certain non-metallic materials, making it suitable for demanding applications requiring deep marking, smooth finishes, and high accuracy.

UV Laser Marking Machine

UV Laser Marking Machines are perfect for high-contrast and low-heat applications. These machines minimize thermal effects, making them ideal for delicate and heat-sensitive materials.

CO2 Laser Marking Machine

CO2 Laser Marking Machines are designed for non-metallic materials, offering excellent versatility for various industries.

Applications:

- Widely used in furniture manufacturing, packaging, advertising displays, and garment production.

- Marking logos, models, and letters on aluminum, including black marking with MOPA technology.

- Used extensively in automotive, aerospace, medical devices, electronics, and jewelry industries.

- Used in pharmaceutical packaging, cosmetic products, food and beverage labeling, and semiconductor components.

Solutions We Provide

Automatic Focus CCD Vision Positioning Fiber Laser Marking

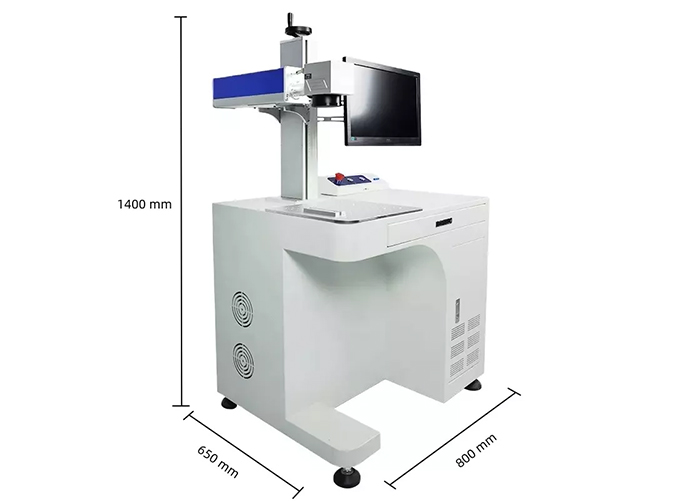

Desktop All-in-one Type Fiber Laser Marking Machine

Enclosed Desktop Type Laser Marking Machine

Desktop Split Type Laser Marking Machine